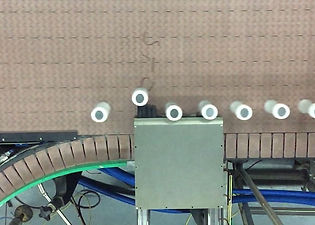

The MultiStep rejection system performs a stable deflection of bottles and containers by means of pneumatic (or motorized, depending on model) actuation of finger-shaped segments, avoiding impacts and falls.

Ensuring product quality and optimizing packaging line efficiency is made possible by E2M’s Multistep reject system.

In production processes, the phase comprising the packaging line is a key moment that, without effective quality control and separation systems, can lead to significant losses.

Rejection of defective or non-production packaging is an effective solution for reducing operating costs and meeting quality standards and demands.

The MultiStep reject and division system performs a stable diversion of bottles and other vessels without causing damage, avoiding falls or other impacts by a pneumatic or motorized performance.

MultiStep for the rejection and division of bottles

This innovative, integrated and stable reject system stands out in the market for valuable features such as:

-

Compact and quiet equipment

-

Robustness and durability, with a stainless steel and soundproof housing

-

Minimal preventive maintenance

-

Easy to install and manage

In this system, each packaging format has associated a set of parameters that will be changed very quickly through completely intuitive configuration applications.

MultiStep has two series for different usage scenarios:

-

SS Series: for standard and small size containers, with minimum space of 25mm between consecutive containers, ideal for low to very high-performance production lines.

-

V Series: for large and very large bottles, including bottles, ideal for low to medium high-performance production lines. Supports waterjet hygiene for dairy drip lines.

Multistep Rejection Systems, together with inspection systems, provide agility to production ensuring the highest quality

FEATURES

-

Rejection / Divider System

-

Stainless steel case

-

Control unit

-

TFT touch screen

-

Rejection or splitter system management (1 to 4 ways)

-

Management of digital and analog signals of external inspection, pressure switch, Encoder signal

ADVANTAGE

-

Silent system

-

Easy installation on the existing conveyor

-

Compact and robust design

-

Minimum preventive maintenance

-

Long-life system and fast amortization

-

Water jet cleaning for dripping lines of dairy or sticky content (MS Series V)

-

Intuitive format change

-

Compatible with third-party inspection systems

-

Configurable division strategies

DESCRIPTION

-

Stable diversion or rejection system

-

Ideal for bottles and other types of containers

-

Stainless steel and soundproof housing

Divert to:

-

Rejection table

-

Adjacent conveyor (Lanning System)

What Does A MULTISTEP Rejection System Do?

Soft rejection-separation-division at high speed