XLE-260 Wrap Around Labeling Machine

The XLE-260 Wrap Around Labeling Machine is a fully automatic labeling solution designed for high-precision, high-efficiency wrap-around labeling of round and oval containers. Utilizing a star-wheel positioning and transmission system, the XLE-260 ensures stable container handling, accurate label placement, and consistent labeling quality even at high production speeds.

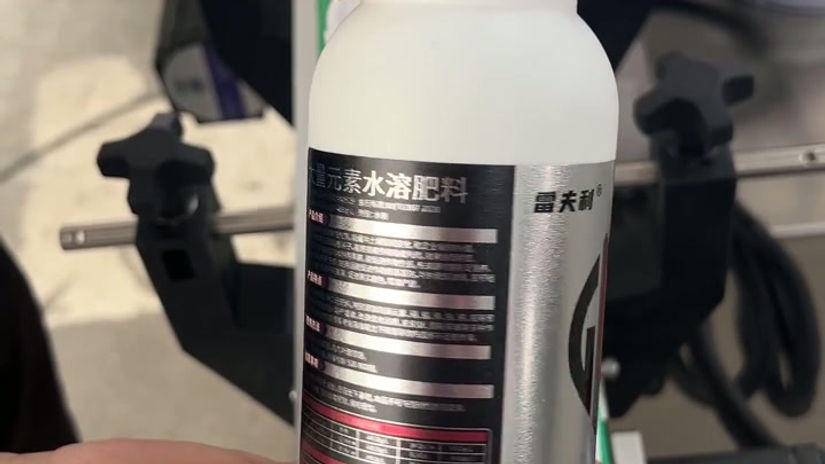

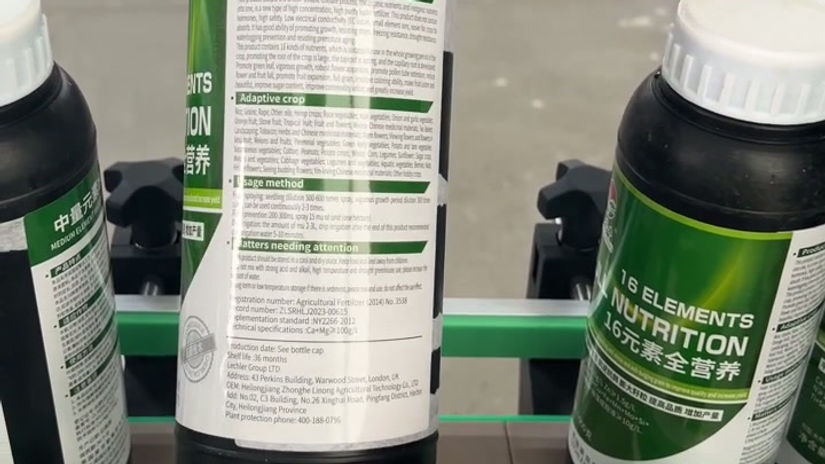

This machine is ideal for manufacturers in the food, beverage, cosmetics, pharmaceutical, and chemical industries who require reliable automation, cleanliness, and professional labeling results on continuous production lines.

XLE-260 Wrap Around Labeling Ma…

Key Features & Advantages

-

Star-Wheel Positioning System

Ensures precise bottle spacing, stable movement, and accurate label placement throughout the labeling process. -

Wrap-Around Labeling Precision

Designed specifically for full or partial wrap-around labeling on cylindrical and oval containers. -

High Labeling Accuracy

Labeling precision up to ±1 mm, delivering consistent brand presentation. -

Stable High-Speed Operation

Maintains labeling quality even during continuous and high-output production. -

Wide Container Compatibility

Supports bottles and containers of various diameters and heights. -

Production Line Ready

Easily integrated into existing conveyor systems and packaging lines.

Applications

The XLE-260 is suitable for a wide range of packaging applications, including:

-

Beverage bottles (juice, tea, water, functional drinks)

-

Food containers (sauces, honey, condiments)

-

Cosmetic and personal care bottles

-

Pharmaceutical containers

-

Chemical and household product packaging

Supported Label Types

-

Self-adhesive paper labels

-

Self-adhesive film labels

-

Product identification labels

-

Barcode and QR code labels

Working Principle

The XLE-260 uses a star-wheel indexing mechanism to precisely position containers before labeling. Once detected, labels are dispensed and wrapped smoothly around the container surface, followed by rolling and smoothing to ensure firm adhesion and a wrinkle-free finish. This synchronized process guarantees reliable performance and uniform labeling results across every unit.

Technical Specifications

Label Specifications

-

Label Length: 20 – 350 mm

-

Label Width (Backing Paper): 20 – 190 mm

-

Max Label Roll Outer Diameter: Ø280 mm

-

Label Core Diameter: Ø76 mm

Performance

-

Labeling Accuracy: ±1 mm

-

Labeling Speed:

-

Stepping Motor: 30 – 60 pcs/min

-

-

Label Feed Speed: 5 – 19 m/min

-

Conveyor Speed: 5 – 18 m/min

Product Specifications

-

Applicable Bottle Diameter: Ø25 – Ø150 mm

-

Applicable Bottle Height: 25 – 300 mm

Electrical & Mechanical

-

Power Supply: 220V / 50Hz

-

Power Consumption:

-

Stepping Motor Version: 570 W

-

Servo Motor Version: 980 W

-

-

Air Pressure Required: 0.4 – 0.6 MPa

-

Machine Weight: Approx. 185 kg