Wrap Around Labeling Machine

Model: XLE-160

The XLE-160 Fully Automatic Round Bottle Rolling Labeling Machine is a high-performance labeling solution designed specifically for round bottles and cylindrical containers.

It integrates automatic bottle conveying, positioning, labeling, and roller smoothing into a single streamlined process, delivering consistent label application with minimal operator involvement.

Overview

With a stable mechanical structure and precise control system, the XLE-160 significantly improves labeling efficiency, accuracy, and production consistency, making it ideal for modern production lines in food, beverage, cosmetics, pharmaceutical, and chemical industries.

Key Features

-

Fully Automatic Operation

-

Complete automation from bottle separation to finished labeled output, reducing labor cost and human error.

-

-

Star-Wheel Positioning & Rolling System

-

Ensures precise bottle alignment and smooth, wrinkle-free label application on round surfaces.

-

-

High Labeling Accuracy

-

Label placement accuracy up to ±1 mm, suitable for premium packaging requirements.

-

-

Wide Application Range

-

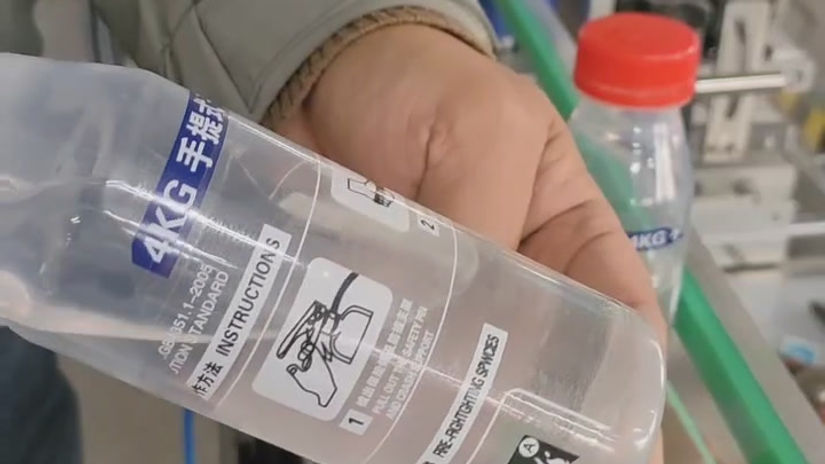

Supports a variety of round bottles including plastic, glass, and metal containers.

-

-

Flexible Labeling Options

-

Capable of single label or front-and-back (double) labeling, with adjustable spacing.

-

-

Integration Ready

-

Can be equipped with inkjet or thermal printers for printing production dates, batch numbers, and codes directly on labels.

-

Typical Applications

-

Beverage bottles (water, juice, spirits, wine)

-

Food jars and containers

-

Cosmetic bottles

-

Pharmaceutical and healthcare packaging

-

Disinfectant and chemical bottles

Working Principle

Bottles are automatically fed onto the conveyor and separated by a bottle-dividing mechanism.

Sensors detect each bottle and trigger the labeling system.

Labels are precisely dispensed and applied to the bottle surface, followed by a rolling mechanism that smooths the label, ensuring firm adhesion and a clean, professional finish.

Technical Specifications

-

Label Length: 20 – 350 mm

-

Label Width (Backing Paper): 20 – 190 mm

-

Bottle Diameter: Ø25 – Ø150 mm

-

Bottle Height: 25 – 300 mm

-

Label Roll Outer Diameter: Ø280 mm

-

Label Roll Inner Diameter: Ø76 mm

-

Labeling Accuracy: ±1 mm

-

Labeling Speed: 30 – 60 bottles/min

-

Conveyor Speed: 5 – 18 m/min

-

Machine Dimensions (L×W×H): 1950 × 1200 × 1530 mm

-

Weight: Approx. 185 kg

-

Power Supply: 220V, 50Hz

-

Power Consumption:

-

Step Motor: 570 W

-

Servo Motor: 980 W

-

-

Air Pressure: 0.4 – 0.6 MPa

Why Choose the XLE-160?

-

Reliable performance for continuous production

-

Consistent, professional labeling quality

-

Suitable for both small and medium-scale production lines

-

Easy integration with existing packaging systems

.jpg)